Subscribe To Emails

Subscribe to the YourCotton mailing list to receive updates on new arrivals and promotions (about once every 6 weeks)!

You're not alone if you've ever found yourself curious about how to sublimate on cotton! The good news is that the process has become a lot simpler and easier over time. Sublimation printing involves transferring graphics and photos onto fabric, textiles, or other products with special dyes that use heat for transfer. It's becoming increasingly popular for business owners who are looking for ways to differentiate their products from the competition. Now, there’s no need to worry about details like equipment setup or ink compatibility because we are here to help you unlock all of the secrets of customizing cotton materials with sublimation printing!

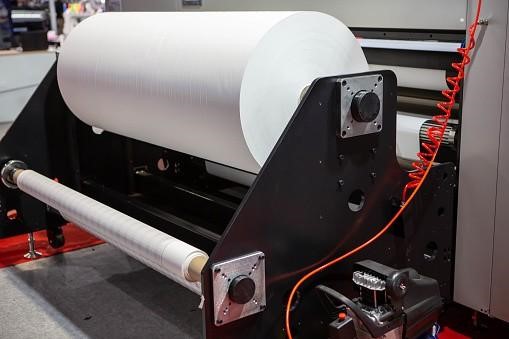

Sublimation is converting materials from a solid to a gas state without passing through the liquid form. It typically requires sublimation ink, a sublimation printer, and polyester or polymer-coated substrates to produce a sublimation print. A common material used for sublimation is cotton shirts.

The process begins by printing sublimation inks on sublimation transfer paper using special sublimation printers, which then subline the image onto the fabric of the clothing item. Subsequently, the garment is heated up, causing the parts to vaporize and bond with the fibers of the shirt, resulting in a vibrant and detailed design that is breathable and comfortable to wear. All in all, sublimation offers an excellent way to dress up fashion items with vivid printed designs.

Sublimation prints on fabrics other than 100% cotton are popular for creating beautiful personal items like mugs and t-shirts. However, 100% cotton fabric does not sublimate as easily, and this presents a challenge.

Fortunately, it is possible to sublimate on 100% cotton with some unique treatments. These treatments include using sublimation paper, applying heat transfer vinyl, or coating the surface of the cotton with a special liquid before sublimation projects can take place with a heat press. By investing in these products, you can start sublimating unique creations onto your fabric of choice!

Sublimation printing is an option when dyeing certain cotton garments or other fabrics. The process involves inkjet printers and special dye sublimation paper. To achieve the bonding that sublimation requires, these garments must be exposed to higher temperatures which range from 360℉ to 400℉.

It is important to note that hand-held irons and simple ironing boards will not be able to generate enough heat for actual dye sublimation. Cricut Design Space provides general guidelines for working with dye sublimation but recommended heat press times and settings can usually be found on the packages of dye transfer paper.

Whether you are a novice or an expert, sublimating on cotton is possible with the right knowledge and supplies. The essential element to keep in mind is that some kind of intermediary material needs to be utilized for successful dye transfer - vinyl works great for this purpose and you can also buy special synthetic coatings designed explicitly for cotton fabrics. With these methods, home crafters will surely achieve excellent results!

Sublimating onto cotton using vinyl is an easy and effective way to create personalized items. Start by pressing a polyester shirt to preheat the area you want to sublimate your design. Tape any areas around the heat press plate to prevent ink from entering those regions. Once the correct heat and pressure are applied, place the heat-resistant tape over your printed design and use the heat press to complete the sublimation process. Remove the heat tape afterward, making sure all pieces of it are taken off, leaving a vivid imprint of your custom sublimation design on your garment!

Sublimating on cotton with glitter HTV may seem like a daunting task. However, the results can be stunning and transforming! To begin, you'll need to choose your design and decide which type of HTV you want. Cotton works best for Glitter Iron-on Vinyl because it gives the design more body, allowing the glittery effect to fully pop.

When selecting your fabric, ensure it is prewashed since this will attract more ink from the printer. Temperature and time settings may differ depending on certain brands of Iron-on Vinyl, so don't forget to look out for instructions to ensure an optimal result. Afterward, all that's left is to determine where to place these glittery new designs!

Sublimating on cotton can be a great way to make unique and personalized clothing or accessories. With spray coating, you can achieve this look with relative ease! The first step is to prep the garment, cleaning it with a degreasing product so that the sublimation ink sticks evenly. Next, set your iron to medium heat and press the material for around 30 seconds.

Then, you'll need to apply several thin coats of spray coating, making sure to allow each coat adequate drying time in between applications. Place your printed design face down onto the garment and use pressure-sensitive tape at the corners. Finally, use parchment paper over the top and then press again for 60-90 seconds using medium heat on an iron – voilà! You will have your personalized item of clothing featuring vibrant colors that will last for years to come.

Sublimating onto cotton is a great way to add some unique flair to your wardrobe! All you need is sublimation fabric sheets, an inkjet printer, any type of heat press, and a flat surface. Simply print the design on the fabric sheet and heat-press it onto the cotton item. Be sure that you are pressing it firmly so that all areas of the design are transferred onto the material.

Your heat press must be set at a temperature appropriate for both the inkjet paper and material – typically 400 degrees Fahrenheit (204 degrees Celsius). When done correctly, you’ll be left with vibrant colors that won't wash away – perfect for making personalized shirts or window curtains! With just these few steps, you can turn your creative vision into a colorful reality like never before.

Sublimating on cotton can often be tricky, but you can accomplish your desired results with the proper methods and materials. To sublimate on dark cotton, you need to ensure that the dyes used are both acid and disperse dyes. Make sure to use ink formulated for sublimation printing. Once these items are in check, you will want to pre-press your apparel before printing.

This involves pressing each side of the fabric with heat for at least 12 seconds to prevent ghosting or blurring of your image on darker fabric. Next, print your image onto transfer paper using a heat press set between 280-330°F. After that, align the printed paper to the apparel and press it again at 350°F for 30 seconds using light pressure. If done correctly, your design should have successfully transferred from the paper over onto the cotton fabric!